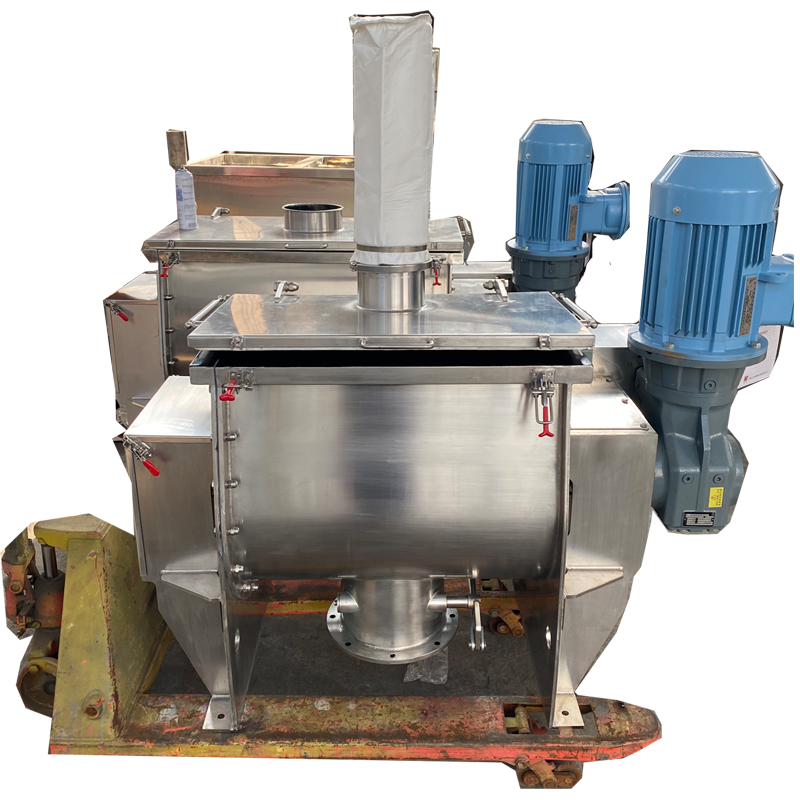

Horizontal Ribbon Blender Mixer

Horizontal Ribbon Blender Mixer mainly used for the mixing of sticky or cohesive powder particles and the mixing of liquid and paste materials in the powder particles.

At the same time, due to the difficult cleaning of viscous materials, it is suitable for the mixing of large yield and not often changing varieties.

Description

Brief Introduction:

Horizontal Ribbon Blender Mixer mainly used for the mixing of sticky or cohesive powder particles and the mixing of liquid and paste materials in the powder particles.

At the same time, due to the difficult cleaning of viscous materials, it is suitable for the mixing of large yield and not often changing varieties.

Structure Characteristics:

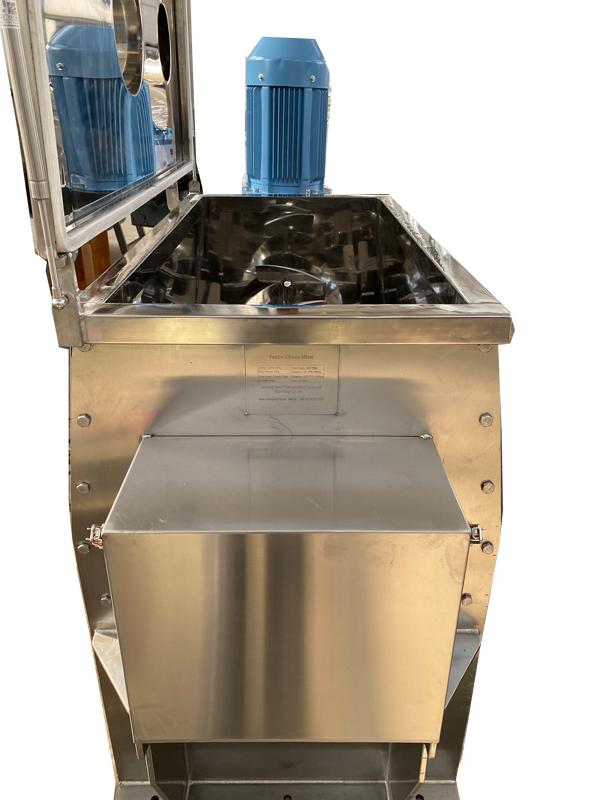

- Composed of U-type cylinder, ribbon blender, spray nozzle, loading head cover, discharge device and motor-gearing device and electric cabinet

- U-shaped long cylinder structure ensures the small resistance movement of the mixture (powder, semi-fluid) in the cylinder

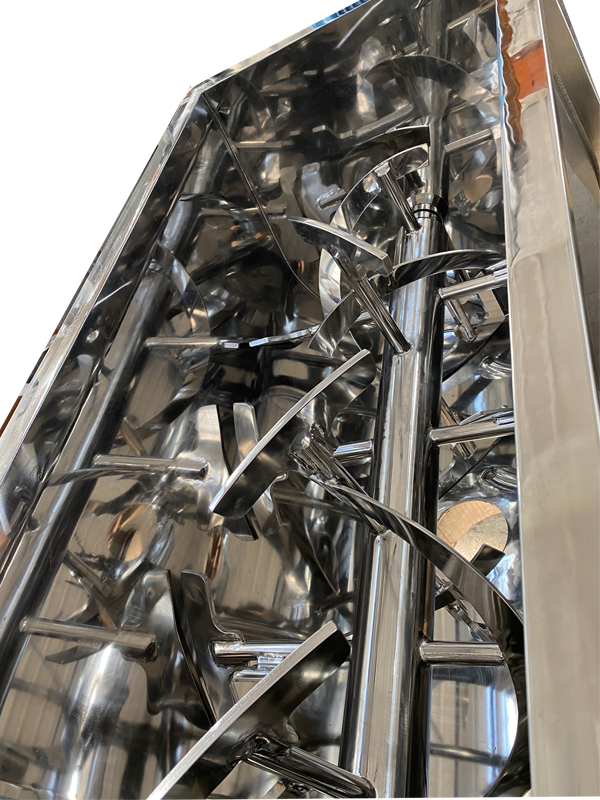

- The positive and reverse rotating ribbon blender is installed on the same horizontal axis, forming a low power and efficient mixed environment. The ribbon blender is generally made into double or three layers. The outer spiral collects the material from both sides to the center, and the inner spiral transfers the material from the center to both sides, which can make the material form more vortex in the flow. Accelerate the mixing speed, improve the mixing uniformity;

- Horizontal ribbon blender mixer is a high efficiency, high uniformity, high loading coefficient, low energy consumption, low pollution, and low crushing type mixing equipment.

- It is applicable into a wild range, which as powder and powder, powder and liquid mixing, especially in paste, sticky or large proportion of materials (such as putty, true stone paint, metal powder and other products).

Discharge Mode:

The powder material adopts the form of large pneumatic door structure, with the advantages of fast unloading and no residue; high fine materials or semi-fluid materials adopt pneumatic valve, which can be configured with heating or cooling jacket.

Heating Mode:

There are two heating methods: electric heating and thermal oil heating.

Cooling Mode:

The cooling process can directly inject cooling water into the jacket, the jacket heat exchange with large area and fast cooling speed.

Spray Nozzle Device

Pneumatic or Liquid Spray Nozzle

Atomization or liquefaction Spray Design

Blade Device

During mixing period, particles adhered into groups, high speed rotating blade scattering the particles groups

Gearing Device

The small size mixer adopts the reducer direct connection mode, with simple structure, high operation reliability and convenient maintenance.

The large mixer is driven by pulley drive reducer. The elastic connection of belt drive has the advantage of protecting the transmission parts when overloaded.

Application Range:

Pesticides, veterinary drugs, food, chemicals, biology, biology, aquaculture, ceramics, refractory materials, plastic, compound fertilizer and other solid-solid (i.e. powder and powder) solid-slurry (i. e. powder and glue slurry) mixing, but also particularly suitable for sticky material mixing.