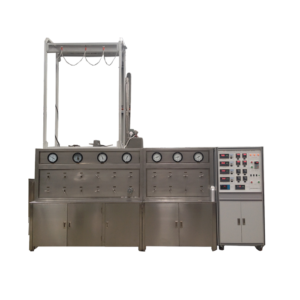

150L x 2 Industrial Scale Supercritical Co2 Fluid Extraction System

Description

150L x 2 Industrial Scale Supercritical Co2 Extraction System

150L x 2 Pilot Scale Supercritical Co2 Extraction System with 2 set of 30 lter extraction vessel, 2 to 3 separators, working for pilot scale test and research of SC-Co2 system.

Brief Introduction:

This kind of system is workable for high pressure and suitable temperature extraction material (solid & liquid), changing condition to make the solvable material resolve the target product during extraction and separation.

The whole system included extraction reactor, separator, CO2 high pressure pump. Cooling system, heat exchange system, CO2 storage tank, liquid level meter, purifying filter system, flow meter, temperature control system, security protection system, charging and loading system etc. All the main machinery and auxiliary equipment could satisfy supercritical extraction system and technical process requirement.

Process Design:

Liquid Co2 from pressured bottle or storage tank, through pipeline into purifying part, cooling part, mixer part, after heated and transferred into extractor, where solid raw material loading into barrel feeding into extractor, with dissolve ability to extracting, through temperature and pressure condition change, separated target material in separator. Separated material without chemical solution remained, Co2 would be gasifying after few seconds.

Characteristics & Features:

1. Supercritical CO2 fluid is non-toxic and non-combustible, which is conducive to safe production, and has rich sources, low price is conducive to promotion and application, and cost reduction. And this process of equipment is closed circuit, CO2 can be recycled in the device.

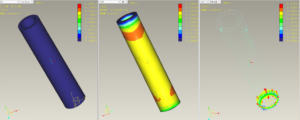

2. Each high pressure vessel on the equipment is subjected to professional 3 D software stress analysis to ensure the service life of the equipment.

3. The overall support of the equipment is made of 304 stainless steel, which is safe and stable

4. The control interface can monitor the pressure, temperature, flow and other data in real time, and can set the temperature and pump frequency.

150L x 2 Industrial Scale SC-Co2 System Technical Specification:

Extraction volume: 150 liter x 2 extractors

Separation Volume: 5 liter or 10 liter

Separator Quantity: 2 to 3 separators

Extraction Pressure: Maximum to 50 Mpa

Separation Pressure: Maximum to 28 Mpa

Temperature Range: 0~120C

PLC automatically control system, data record collect and romove control system. fully automatical pressure and temperature, Co2 recovery and circulation system.

Our Factory: