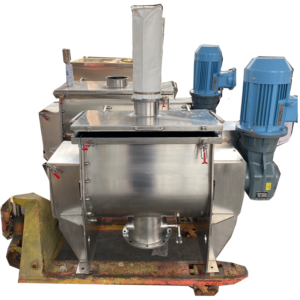

DLH Series Horizontal Ribbon Mixer

Horizontal Ribbon Mixer installed by U type cylinder, ribbon blender blade and transmission part. Ribbon blender blade usually designed in double or three layers, outer ribbon blender bring powder material from side parts into middle area gathering, inner ribbon blender bring powder material from middle area to side parts outputting, occurred convective mixture. Ribbon blender mixer with a good mixing effect for viscous or cohesive powder material, and also suitable for pasty material which with liquid added during mixing. The mixer cylinder cover can be made into a full door structure to clean the equipment and replace the accessories.

Description

Brief Introduction:

Horizontal Ribbon Mixer installed by U type cylinder, ribbon blender blade and transmission part. Ribbon blender blade usually designed in double or three layers, outer ribbon blender bring powder material from side parts into middle area gathering, inner ribbon blender bring powder material from middle area to side parts outputting, occurred convective mixture. Ribbon blender mixer with a good mixing effect for viscous or cohesive powder material, and also suitable for pasty material which with liquid added during mixing. The mixer cylinder cover can be made into a full door structure to clean the equipment and replace the accessories.

Working Principle:

Horizontal Ribbon Mixer working under the installed inner and outer ribbon blender on main shaft part, the ribbon part designed in inner and outer, left and right reverse rotation, which could blending fully powder material in inside cylinder, during mixing, inner ribbon bring material into shaft core direction rotating, shaft rotating from inside to outside, outer ribbon bring sidewall material into shaft core part direction, which occurs convective circulating mixing inside cylinder, mixing powder material fast uniform mixing in short time

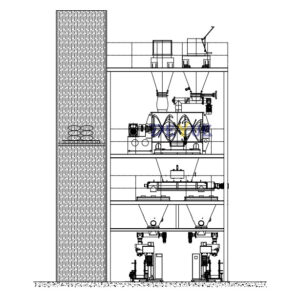

Application Area

Widely used in food, pesticide, chemical, veterinary medicine, aquaculture, new materials and other fields, can achieved powder and powder, powder and liquid mixing, especially mixing paste, sticky or large proportion of materials, such as putty, real stone paint, metal powder and other products.

Design Features

-

- The equipment designed in a horizontal cylinder, two internal and external layers of ribbon blenders, stable operation, reliable quality, low noisy, long service life, convenient installation and maintenance, and multiple mixing structure.

- High speed mixing, high mixing uniformity, especially for viscous materials, the scraper can be installed on the ribbon blender, which also has a good mixing effect on viscous materials.

- Under different mixing requirements of materials (when special materials must be cleaned before and after each mixing), different ribbon blending structure can realize heating, drying and other functions.

- The positive and reverse rotation of the ribbon installed on the same horizontal axis, forming a low power high efficiency of mixing environment, smooth mixing process to reduce the destruction of fragile materials, if the mixing process need to further crushing in the material, can add scraper structure for further damage effect, equipment can also increase the spray system, better realize the mixture of liquid and powder evenly mixing.

- The movable door can be cleaned on the horizontal body, so that the equipment can be cleaned internally. The overall height of the equipment is moderate and easy to install.

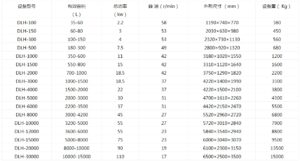

Remarks:

- The mixing amount in the table is the measured data with the material accumulation density of 1.0 as the medium. The equipment selection should be calculated according to the number of products, material accumulation density, liquidity and other parameters.

- If there is high temperature, high pressure, flammable, explosive, corrosive, viscosity and other working conditions, detailed data must be provided to facilitate type selection.

Equipment Superiority:

- Widely application range, small destructive: horizontal structure with a unique double ribbon design, not only be powder and powder mixing, but also suitable for powder and liquid mixing, and could achieve the mixing between paste, sticky or large proportion of materials.

- High equipment stability, long service life: the reducer has the advantages of high output torque, low noisy, long gear life, not easy oil leakage, etc. The discharge valve adopts considerate arc-type valve, mixed without dead Angle, the new valve body structure design to ensure the service life and sealing effect of the valve.

- The loading rate is high, strong sealing: according to different material characteristics, the cylinder can be designed into O or U type, the maximum loading rate can reach 65%, for ultra- fine powder, using air seal + packing composite sealing structure, can greatly improve the service life and effect of sealing, for good liquid slurry, can configure mechanical sealing, meet a variety of conditions.

Non-standard performance: can be customized various types of non-standard products, such as spray type, explosion-proof, heating, vacuum drying type, etc., material can be customized according to demand, carbon steel, 304 stainless steel, 316L stainless steel, polyurethane lining or coating high wear-resistant materials, valve can be customized different material of plum valve, butterfly valve, flip valve or ball valve, etc.